JADO Global Headquarters & Centers

By integrating Administrative Headquarters, R&D Center, Marketing Center, Production Base, and SMT Assembly Line under one cohesive operational framework, JADO Smart achieves seamless collaboration across all functions, accelerating innovation and delivering superior driving safety solutions worldwide.

JADO Smart - Shenzhen Guanlan Manufacturing Base

In 2017, JADO Smart established its headquarters in Longhua Guanlan, Shenzhen, creating an integrated base that combines product design and manufacturing. The headquarters is equipped with hundreds of skilled workers and professional testing equipment, enabling end-to-end service capabilities from concept design to finished product delivery, ensuring that every product meets strict quality standards.

JADO Smart (China) - Shenzhen Bantian Headquarters & R&D Center

The Shenzhen R&D Center of JADO Smart (China) specializes in software development for motorcycle intelligent terminals, covering platform middleware, HMI/navigation, voice and connectivity technologies (Bluetooth/cellular), CAN/diagnostics, and OTA/cloud services engineered for reliability and mass production. The R&D center holds chip agency qualifications and is staffed with professional hardware design engineers who specialize in chip design, related software development and research, product OTA upgrades, and other advanced technical solutions.

JADO(China)-Shenzhen Guanlan Production Base

Since its founding in 2011, JADO Smart has established a 1000㎡ Marketing Center in Guanlan, Shenzhen, operating as an independent facility separate from its headquarters. This dedicated center serves as the strategic hub for brand development and global market expansion, integrating key functions including social media operations, website management, B2B business development, and exhibition planning. The center is staffed with a professional global team and specialized talent equipped to address international challenges, strengthening JADO's brand presence, expanding its worldwide market footprint, and delivering efficient support to partners and customers across the globe.

JADO Smart (China) - Shenzhen Guanlan SMT Assembly Base

Since 2011, JADO Smart (China) has invested RMB 30 million to establish a world-class SMT production workshop at its Guanlan facility in Shenzhen, demonstrating an uncompromising dedication to product excellence. Spanning 400 square meters with a specialized team of 100 quality-focused professionals, this workshop represents JADO's zero-tolerance approach to manufacturing defects.

The facility operates under pharmaceutical-grade Class-100 cleanroom standards with precision SMT assembly lines, implementing real-time quality validation protocols that ensure immediate detection and elimination of any imperfections. Through rigorous in-house control of critical processes including mold fabrication and optical lens production, JADO maintains absolute quality sovereignty over every component, delivering products that exceed international standards for precision, durability, and performance consistency across global markets.

The Development Journey of JADO

Since 2011, JADO Smart (formerly JADO CHINA) has specialized in driving recorder innovation for over 13 years, establishing itself as a high-tech enterprise with world-leading capabilities in premium dash cam R&D and manufacturing. As the parent company of JADO MOTO, we are dedicated to creating safer and smarter travel experiences through products that meet international standards and cutting-edge technologies that integrate the digital world into intelligent driving safety.

Global Structure: JADO Smart (China) manages R&D, manufacturing, and quality control, while JADO MOTO (USA) handles North American market operations, combining manufacturing excellence with localized expertise.

Our Facilities: Production base and marketing center in Guanlan, Shenzhen; administrative headquarters and R&D center in Bantian Tian'an Cloud Valley, Longgang District, Shenzhen—forming a complete industrial chain.

Our Mission: With tens of millions of users served globally, our team and business partners work together toward a shared vision: becoming the global leader in driving safety solutions.

From Vision to Precision — The Complete JADO Production Process

At JADO, every product is born through a rigorous and intelligent manufacturing process. From optical focusing, SMT assembly, and lens dispensing to display lamination and final assembly, each step follows strict quality and dust-free standards. Supported by automated production lines and precision testing systems, JADO ensures that every device leaving the factory embodies reliability, innovation, and craftsmanship.

IQC Incoming Material Inspection

The IQC Center is our first quality checkpoint where all incoming materials undergo rigorous inspection. Equipped with X-ray analyzers, microscopes, and precision testers, our certified engineers examine dimensional accuracy, electrical parameters, and material composition. We implement strict AQL sampling protocols aligned with ISO standards, achieving >99.5% material pass rate with full digital traceability. Only materials meeting stringent requirements enter production, eliminating defects at the source.

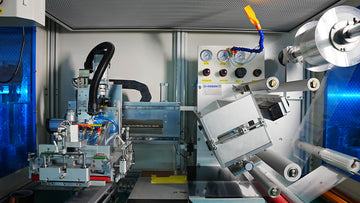

SMT Production Line Overview

Our SMT production floor represents Industry 4.0 intelligent manufacturing. The fully integrated line spans 2,000㎡ Class 100,000 cleanroom with controlled temperature and humidity. Complete configuration includes automatic loading, solder paste printing, high-speed placement, reflow soldering, and AOI inspection. Production capacity reaches 5 million points daily with real-time MES tracking, predictive maintenance, and full traceability. Smart manufacturing features enable flexible high-volume and customized production.

Solder Paste Printing

Automatic printers with vision alignment achieve ±15μm positioning accuracy. Laser-cut nano-coated stencils handle components down to 0.3mm pitch. Lead-free SAC305 solder paste meets RoHS/REACH standards. 100% SPI inspection verifies paste volume, height, and position with ±25μm accuracy. Automatic stencil cleaning every 5-10 prints maintains consistency. Defect rate: <50 PPM. Precise paste deposition ensures flawless component mounting and soldering quality.

High-Speed Component Placement

High-speed chip shooters achieve >80,000 CPH while flexible mounters provide ±0.02mm accuracy. Multiple placement heads with vision systems handle components from 01005 to 50mm packages including QFP, BGA, and CSP. Intelligent feeder management supports 100+ positions with real-time consumption tracking and barcode verification. First-pass yield >99.5%, machine uptime >95%. Combines speed, accuracy, and intelligence for demanding assembly requirements.

Reflow Soldering

Ten-zone nitrogen reflow oven provides independent temperature control, creating optimized thermal profiles for reliable solder joints. Hot air convection heating ensures uniform temperature distribution. Nitrogen atmosphere prevents oxidation, producing full, bright joints. Temperature profiling software controls preheat, soak, reflow, and cooling zones. Real-time monitoring with multiple thermocouples. Cold solder defect rate <10 PPM. Supports lead-free processes meeting international environmental standards.

Manual Assembly Workshop

Lean manufacturing workshop employs U-shaped production lines with standardized operations. IPC-certified technicians perform through-hole soldering, wire assembly, and component integration. Anti-static flooring, ionizing fans, and climate control protect sensitive products. Visual management and Andon alarm systems provide real-time production visibility. Each workstation features electric tools, work instructions, and inspection standards. 100% self-inspection and mutual inspection ensure zero defects flow forward.

Quality Testing and Inspection

Multi-stage testing includes ICT in-circuit testing, functional verification, and environmental stress screening. Advanced equipment performs electrical performance, mechanical strength, and reliability testing. High-low temperature chambers, vibration tables, and aging racks validate product durability. Barcode/QR code tracking enables complete traceability to production batch, materials, operators, and test data. ISO 9001, ISO 14001, IATF 16949 certified. 100% products meet customer specifications before shipment.

Final Packaging and Shipment

Final inspection verifies appearance, dimensions, and functionality. Products undergo cleaning, anti-static packaging, and labeling. Specialized packaging protects against moisture, static, and physical damage during transit. Warehouse management system tracks inventory with FIFO control. Final audit sampling ensures consistent quality. Comprehensive documentation includes test reports, certificates of conformance, and material declarations. Express logistics partnerships enable global delivery. Customer satisfaction rate: >98%.